3,687 total views, 1 views today

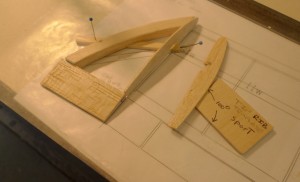

New sloper

Rakete ……………… pronounced Rack – ate or Rack – eight

Lots of color

Development name

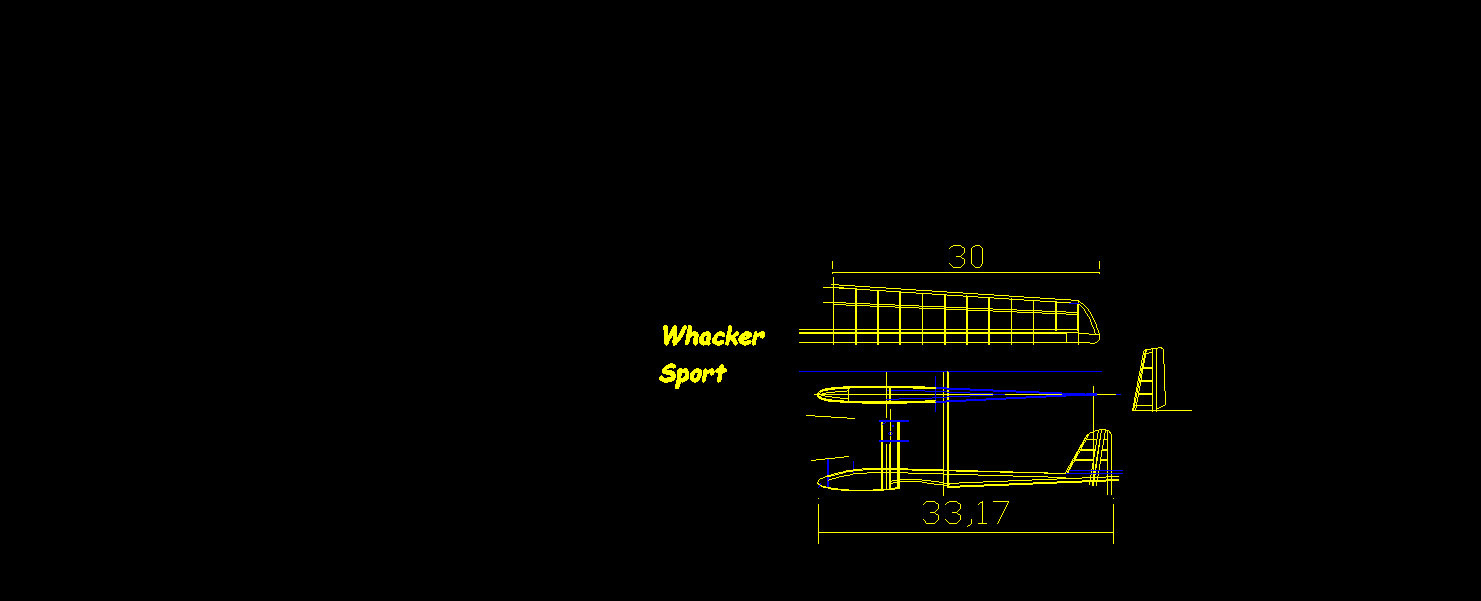

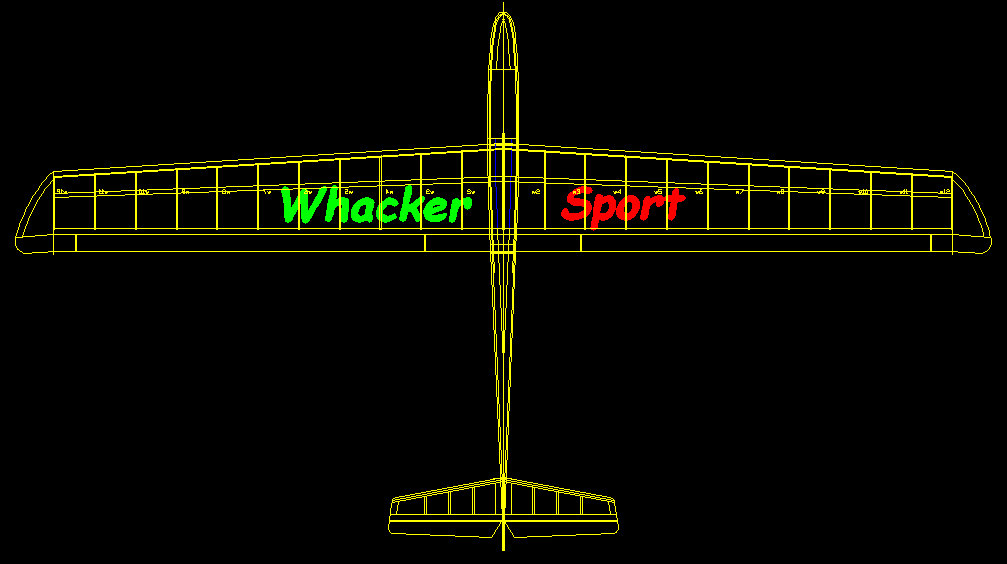

whacker sport

Could it be a or maybe something else?

How about a

Rakete

Gonna go for one piece wing to keep it simple..

wing Held on with rubber bands

Ply wood forward bottom for landing out

Ballast up to 6 oz lead or so.

Good for breeze in access of 10 MPH..

Below that questionable.

Top leading edge sheeted

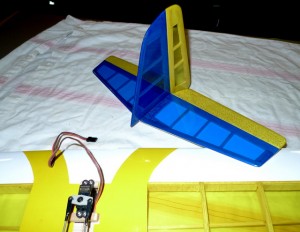

single aileron servo..

Forward fuse from behind wing trailing edge to nose will have ply doubler both sides

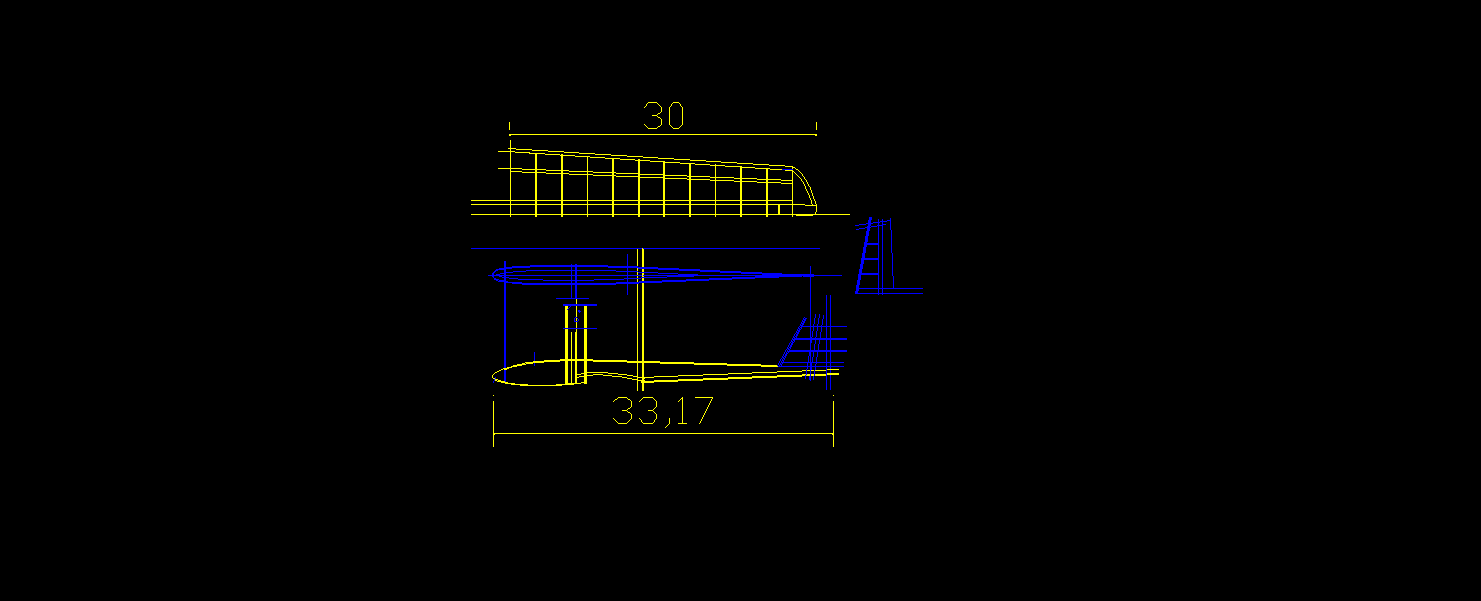

Plan view

Nice proportions 🙂

Nov 18 2014

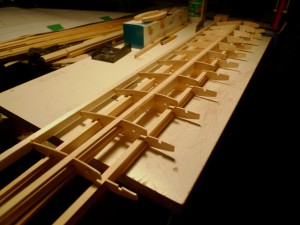

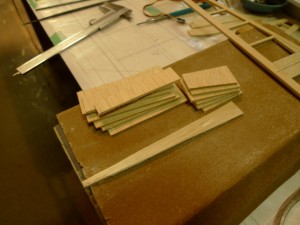

Rib templates, a lot of effort needed here, then I’ll do a mockup with these and do any necessary trimming.

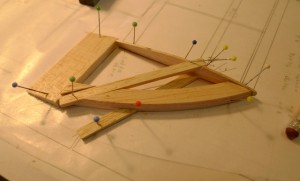

rib template mock up, a little touching up here and there and I can cut the ribs

Nov 19

Parts, more parts the basics are coming together for the wing

first wing half on the board. Small ribs big fingers 🙂

Nov 20

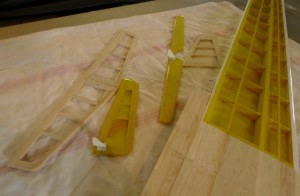

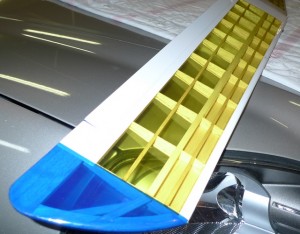

Both wing panels, leading edge missing, as well as top LE sheeting and capstrips. I like these, very easy to build

Nov 21

Leading edge in place. It will need a lot of shaping , very promising though

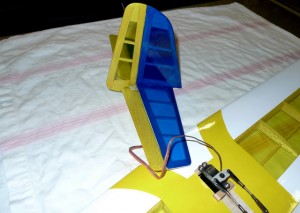

Fin and rudder 30 minutes of cutting and placing and they have taken shape.

Both wing panels, notches were 1st cut into the back side of the leading edge to accept the ribs

Leading edge sheeting

All the parts, the stab is in there as well

Nov 22

Left wing tip, rib set at an angle of 10 degrees

Leading edge sheet

Right wing tip

Both tips

Rib cap strips in place

Inboard pane detail as well as aileron torque rod and tube

Nov 23

Fuselage

sides side doublers a couple formers and a nose block

Wing join , up against a straight edge with one panel flat on board

p

Sides, 1/16 plywood doublers cut and shaped, these get expoxied together later.

Corner fillets in place, still need to be added at bottom corners, fillets are 3/8 triangles, notched where there are curves.

Former , doubled up at the bottom where the wing sets in.

Nov 24

Forward fuse servo and battery compartment.

Servo rail supports and lower triangle in place

A lot less room then what I’m used to in the 2.5M planes . May have to place the servos at an angle .

Tapered ends of upper and lower triangle stock, The fuse side come together at the rear to measure 3/16 wide. I’ll sand them a little so they blend into the rudder which is 1/8 inch thick

Rudder horn in place, rudder reinforced on both sides with some 1/64 ply. This will keep the rudder from crushing. Rudder horn location now allows me to determine pushrod guide exit location.

Wing location, as well as nose block. Just stuck together to see how these parts fit

Pushrod routing and exit out sides at rear, also adding an extra tube for receiver antenna

Forward former in place and glued

Nov26

Stab and elevator. Hinge slots are also in place as well as 1/16 music wire joiner for elevator

Spruce nose block. The fuselage is finally getting it’s figure

Wing saddle doublers inplace

Top and bottom sheeting , 3/32 balsa cut cross grain

Bottom sheeting glued and pinned. Fuse held straight.

All up weight? 11.1 0z No electronics, no covering

Forward upper fuse gets covered

Hatch gets covered here with 3/32 balsa

Lower fuse sheeting

We have a plane. Just had to stick it together for a photo opportunity, wing is still missing it’s entire trailing edge.

Nov 28

Torque rods and trailing edge caps

Hatch cover underside, tongue at front and magnet at rear to hold all in place.

Lower front 1/16 ply sheet

Servo installation, I like to use a piece of lite ply, and set the servos into that, in case the next guy wants to use different servos

Inboard trailing edge, wings still need a lot of sanding.

Trailing edge end piece, app. 1″ long filler.

Next are the details,

– adding wingtips

-slots in ailerons and trailing edges for hinges

– control rods, cutting to length and adding adjustable clevises

– affixing the tail so its square to the fuse and the wing

– sanding

There’s a lot that goes into a build , and it seems the smaller it is the more work it takes

Nov 29

Right wing tip set at 10 Deg up to underside of wing.

Left wing tip

Ailerons in place to show full wing chord.

Dec 3

Lots of transparent yellow, wing upper and lower, elevator and rudder

A splash of blue for the tips

Fuselage 2nd coat of white

Dec 05

Paint takes a while too dry, 1 day between coats so today I got the top coat of white on..

I’d like too add a blue swirl not sure yet though what that will be

Dec 06 2014

608 Grams 21.4 oz a little heavier then I thought 2.3 sq. ft of wing

yields 9.3 oz / sq. ft Huum